Niiro Chakushoku (Boiling Color Patination)

Rôgin/Oborogin and Karasugane/Ukin

These are names of metals from Japan’s past. They refer to colors. They achieve something similar to the delicate nuances of color found in nature. They speak of the refinement of the Japanese who found so many different names for them.

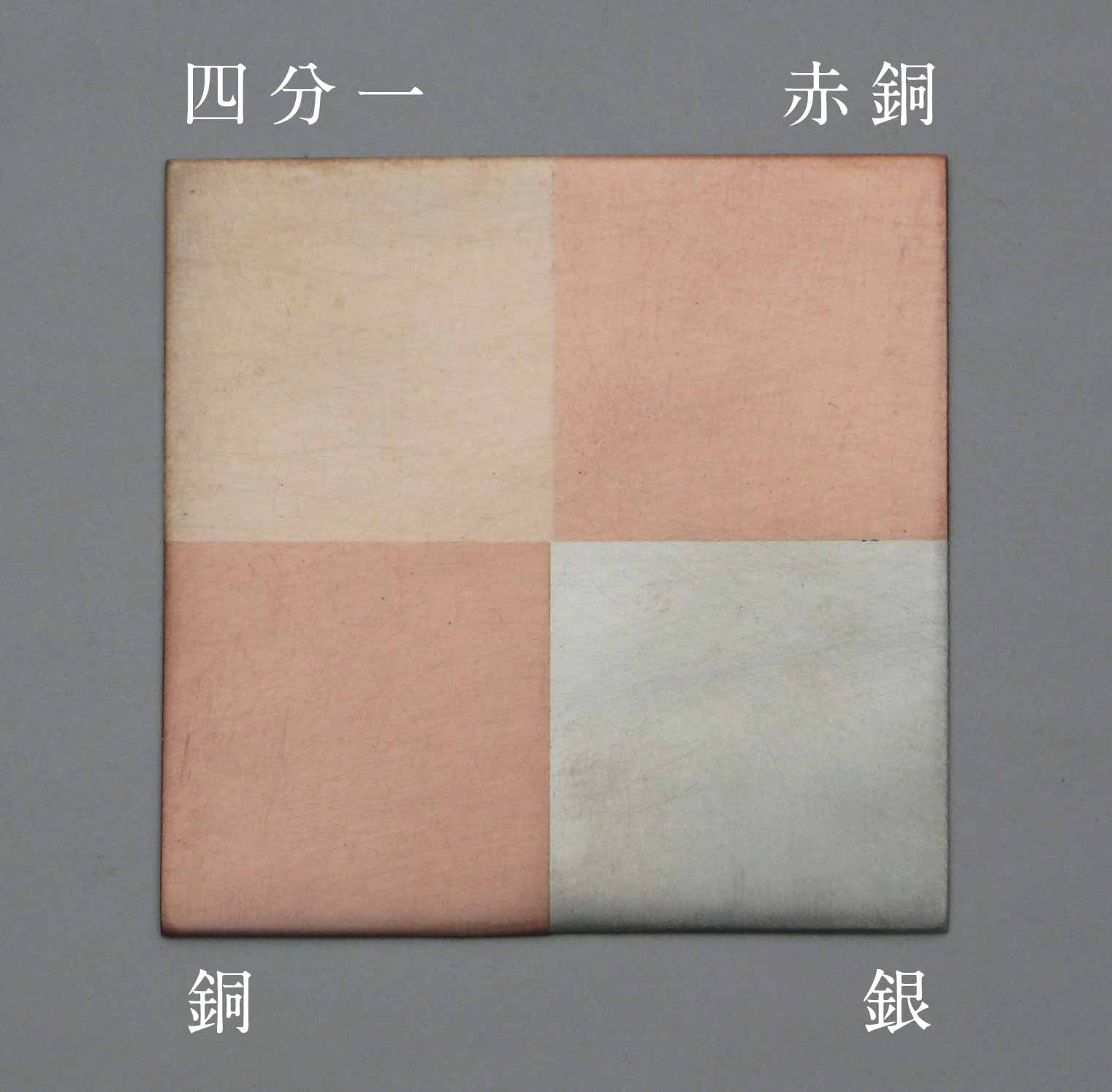

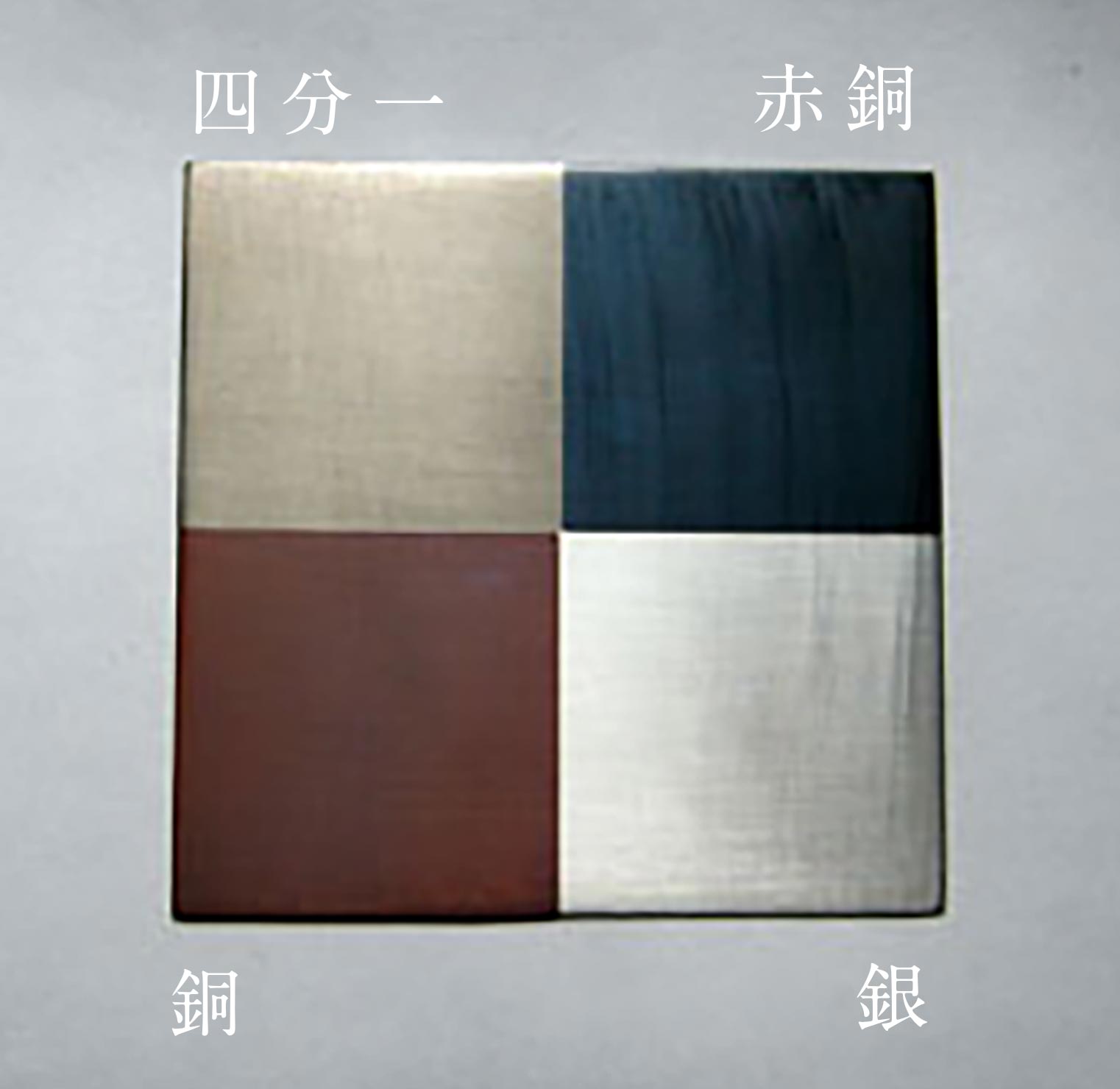

During the Edo period, in addition to gold, silver and copper, mokume-gane was made using uniquely Japanese alloys such as shibuichi and shakudo. Patterns could be created thanks to the differences in color of these metals. Since, in their raw state, these copper alloys look no different from copper, it is hard to see the difference when they are layered with silver and copper and twisted or carved. It is with the final traditional technique known as boiled color patination that the color changes and that the intricate mokume-gane pattern becomes visible.

“Oborogin” is the name given to shibuichi after the boiled color patination. The term “Oboro” comes from “Oborotsukiyo” which refers to spring nights with a hazy moon, resonating with the actual color. The name suggests a layer of mist upon a brightly shining moon. The alloy consists of one part silver to three parts copper. “Karasugane” is another name for shakudo. The name comes from the resemblance to a crow’s feathers when wet. It is an alloy of copper and gold, with the proportion of gold varying from 1% to 5%.

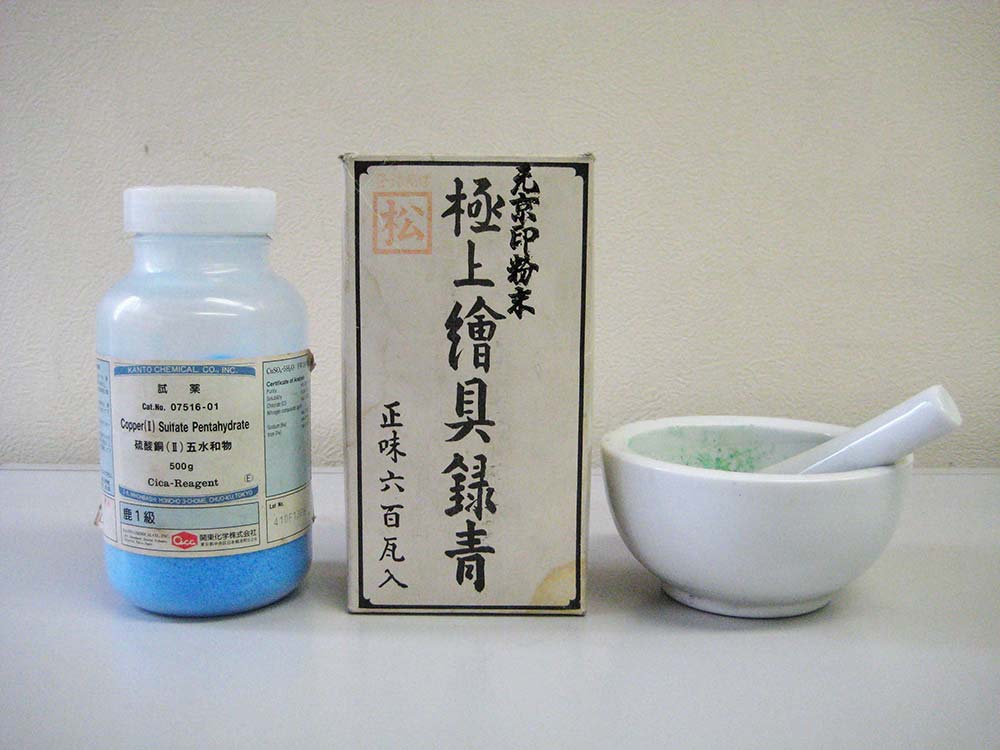

Boiled color patination is a method whereby copper sulphate and Rokusho pigment are mixed with water, brought to the boil, and then boiled until the color is achieved.

When the boiling process is carried out, the surface must be polished so that there is not even the slightest irregularity nor any oxide film. To achieve this, the alloy is dipped, just before boiling, in water mixed with finely grated daikon radish, a method that has been transmitted unchanged from olden times.

The patinated alloy that has changed color has a thin film on its surface. You could say that it is a rusted surface. If this thin film is rubbed too hard, it will gradually disappear, so it is covered with either wax or a thin film of transparent paint. This is what makes it a challenge to use in modern jewelry.

At Mokumeganeya, we have been working on developing our technology in using gold and platinum, rather than copper alloys, in order to enhance the attractiveness of mokume-gane in modern times. Since the pattern is produced by the colors of the actual metals that are used, our aim is for mokume-gane patterns that you will be able to enjoy each and every day as you wear the pieces. We are making further efforts with regard to the layering of these precious metals, and that is what we will be discussing in our next chapter.